- Carding Engine

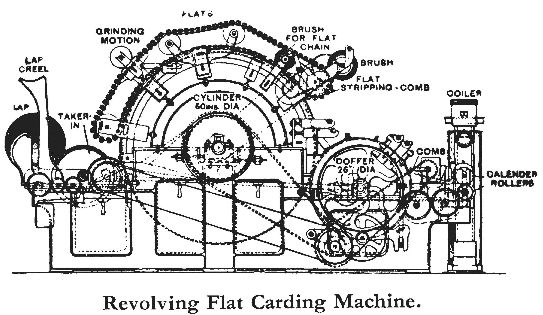

- CARDING ENGINEThe laps from the scutcher are placed on a roller, which by revolving, causes the lap to unwind. It is then gripped between a dish feeder or plate and a fluted feed roller. The projecting end of the lap is then pulled through by the teeth of the taker in, and (passing over mote knives and bars or grids) is laid on to the cylinder. The object of the mote knives is to take out a quantity of the heavier dirt. The cotton is carried forward on the surface of the wire with which the cylinder is covered, and brought into contact with similar wire on rollers or flats. As these latter travel very slowly and the cylinder revolves at a high surface speed, the cotton is combed between them, and is gradually carried towards the doffer (also covered with wire). The slow surface speed of the doffer strips the cotton from the cylinder, and the doffer in turn is stripped by an oscillating comb. The web from this comb is condensed into silver by passing through a trumpet and a pair of calender rollers and delivered through a coiler. It is afterwards coiled in layers into a card can. The width of the card varies according to the kind of cotton being treated. In common practice for Indian Chinese and the low grade cottons 45 in wide machines are usually adopted for American, 40 in , 41 in wide Egyptian and Sea Islands, 37 in or 38 in wide, with cylinders 50 in diameter, 9 in take-in and doffers 24 in, 26 in , or 27 in diameter. The revolving Flat Card is shown here

Dictionary of the English textile terms. 2014.